LONG's TCP has patents from many countries

Electronic Technology Album-LONG’s Thin Carrier Plate, the carrier revolution, will gradually replace traditional CP and JIG plate. It has obtained patents in Japan, South Korea and other countries, and has been adopted by international manufacturers such as Samsung

General Manager, Lin, Sen-Sung

LONG Automatic Machinery Co., Ltd., which successfully developed a new MLCC carrier plate "Thin Carrier Plate" in May 2006, has obtained patent licenses from Japan, South Korea, Mainland China and Taiwan, and is used by Japan, Taiwan, South Korea, Europe, the United States and other major manufacturers. It will gradually replace the traditional CP and JIG plate, with unlimited future development prospects. The following is a summary of the interview with Lin, Sen-Sung, general manager of the company:

Question: What is the reason for the development of Thin Carrier Plate?

Answer: The cost of consumables for CP is high, and the pins are easy to break during the process, causing inconvenience in changing the pins, and no dipping at one end; as for JIG plate, it has quality and appearance issue such as scrap paste, chip with residual glue, and slant dipping during the process. Five years ago, South Korea's Samsung noted problems in the process of CP and JIG plate, so it actively visited manufacturers from various countries and requested the development of new carrier plates, hoping to achieve new demands such as automation of the dipping process, high quality, and lowering the cost of consumables. Due to technical problems, we are not able to launch Thin Carrier Plate on the market for a long time. It was not until November 2005 that we discussed the R&D plan with the company again. After seven months, the technical bottleneck was finally overcome. Samsung tried it for ten months, and immediately purchased and used in large quantities, the new era of Thin Carrier Plate use officially opened.

Question: Let’s talk about the R&D process and progress of Thin Carrier Plate equipment.

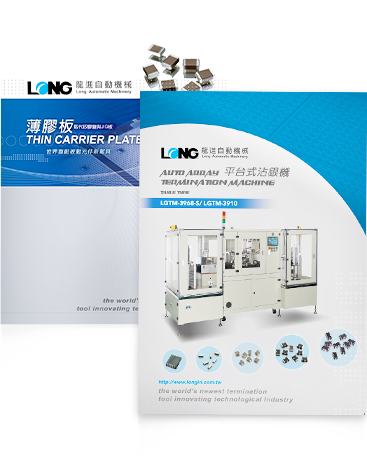

Answer: In the R&D process of the Thin Carrier Plate, we did the equipment research and development in parallel. In May 2006, the Thin Carrier Plate was announced to be completed; at the end of 2006, the automatic Thin Carrier Plate dipping machine model was successfully developed. In conjunction with the fully automatic transferring and unloading machine to be launched in August this year, and the fully automatic chip inserting machine to be launched at the end of this year, it will achieve the requirements of simplicity, labor saving, and automation.

In addition, the development of Array Thin Carrier Plate dipping machine is based on the requirements of LTCC for high-quality dipping and high yield. It is expected to be launched in August this year; and a series of processes such as loading, dipping, drying, and unloading are connected. , The dipping equipment that can save manpower and maximize production capacity is also expected to be launched in 2008.

Question: What is the future market prospect of Thin Carrier Plate?

Answer: The replacement of old carrier plate and new carrier plate is unstoppable, and it is also a part of competitiveness. The successful use of Thin Carrier Plates has attracted the attention of major MLCC manufacturers in the world. It is expected that orders will be flooded in the second half of this year. South Korea's Samsung expects that 50% of the process will be replaced with Thin Carrier Plates by the end of this year. It is expected that all the replacements will be completed in 2008, and the new era of using Thin Carrier Plates has come.

2007/05/21 Business Times

Translator: Lin, Yupei