LONG Developed Full Automatic Dipping System

LONG Automatic Machinery Co., Ltd., which successfully developed passive component chip carrier "TPC Thin Carrier Plate", and related machinery and equipment, has an increasing operation recently. At present, most major domestic and foreign passive component MLCC manufacturers have gradually abandoned previously commonly used CP and JIG plate, and switched to LONG's TCP dipping machine system, which received unanimous reputation. The effect of "new for old" has gradually been fermented in the industry, forming a new revolution in MLCC carriers.

Lin, Sen-Sung, general manager of LONG Automatic Machinery, said that after the company launched the "TCP" and its peripheral related machinery and equipment, it has injected considerable benefits into the company's performance and revenue, and its performance has grown by multiples. Lin, Sen-Sung said that compare LONG’s TCP and traditional JIG plate, after testing, the defect rate of traditional JIG plate is almost 15 times more than TCP; from cost-wise, the cost of TCP is only 1/3 compate to traditional JIG plate. With the relative advantages of improving quality and reducing the cost of consumables, it has attracted major global manufacturers from Japan, South Korea, mainland China, Southeast Asia, Europe and the United States to designate and adopt it.

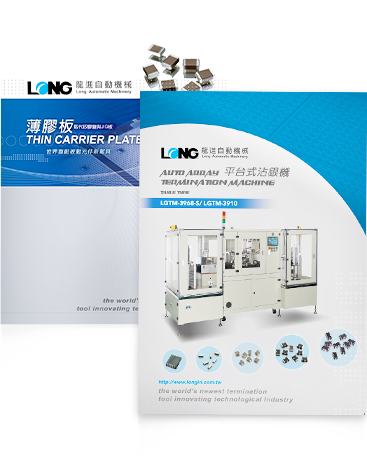

In order to cope with the use of TCP, LONG has also successively developed a series of related mechanical equipment, such as automatic dipping machine, automatic transfer/unload machine, semi-automatic ATCP insert machine, automatic insert/level machine and many other models. What is even more gratifying is that in last September, LONG successfully launched the "full automatic dipping system" with 7 steps of chip insert, dipping, drying, transferring, dipping, drying, and unloading. It saves a lot of labor costs and has been purchased and used by major factories in the world.

Lin, Sen-Sung said that the main material of TCP is stainless steel and silicone, which meets the environmental protection issues and non-polluting characteristics. The product focuses on improving quality and reducing the cost of consumables. It has good clamping force, high precision and its "light and thin" feature eliminates the inconvenience and energy consumption of the old CP and JIG plate in operation. In addition to light weight, thin thickness, high strength and fast heat dissipation functions, TCP can increase yield and reduce costs. Take CP as an example, its disadvantages are that the pins are easily broken, the material is heavy, one end is not stained with silver, the heat dissipation is slow, and the energy consumption is lacking; as for JIG plate, it is easy to scrap silver, contain residual glue, has oblique dipping appearance, has chip residue on the plate after unload, high chip size requirements, and difficult to control the size of dipping.; TCP, Thin Carrier Plate, is easy to operate, high yield, low consumable cost, and could automatic supply and collect paste.

Lin, Sen-Sung said that the company is striving for the perfection of related equipment for multilayer ceramic chip dipping, and new functional machines are also under continuous development. LONG will launch 0204 Array dipping process in the end of March. This product is aimed at implant technology and latest industry demand. After long-term testing, it has the characteristics of beautiful appearance, high dipping rate, stable quality, low consumable cost, both long and short sides can be dipped, and the production capacity can reach more than 180,000 PC/HR. Website: https://www.longdip.com/

Translator: Lin, Yupei