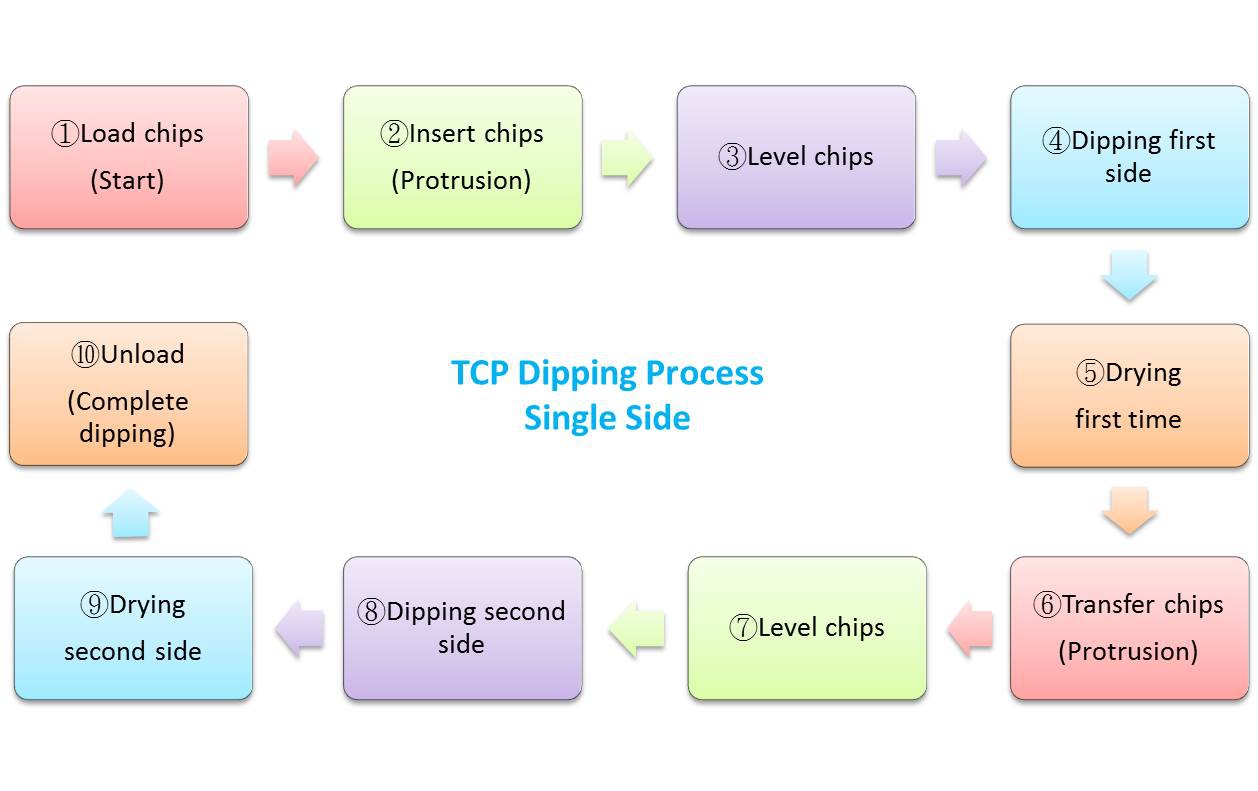

TCP Dipping Process- Single Side

2020-04-09

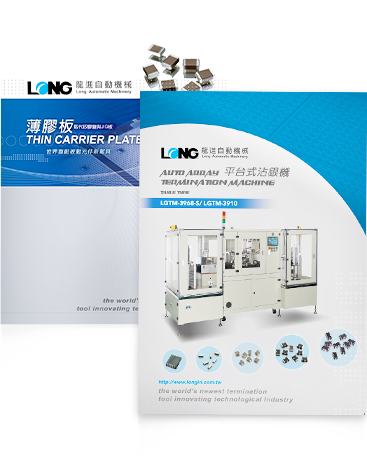

Single Side Dipping Process from Top Inserting: For 0805(2012mm) above chips

| Dipping Process | Equipment | Equipment |

|---|---|---|

| ① Load Chips | Chip Loading Box, Loading Machine | Load Plate, Support Plate, Carrier Plate (TCP) |

| ② Insert Chips (Protrusion) | Air Press from Top | Top Press Conversion, Pins, Spacer for Top Insert, Unload Plate |

| ③ Level Chips | Air Press for Level | Bottom Level Plate (with flatness), Spacer for Level |

| ④ Dipping First side | TCP Series Dipping Machine (LGTM-6822、LGTM-6191、LGTM-6168) | Vacuum Plate |

| ⑤ Drying First time | Dryer | TCP Cassette |

| ⑥ Transfer Chips (Protrusion) | Air Press from Top | Top Press Conversion, Unload Plate (with holes), Spacer for Transfer |

| ⑦ Level Chips | Air Press for Level | Bottom Level Plate (Flatness), Spacer for Level |

| ⑧Dipping Second side | TCP Series Dipping Machine (LGTM-6822、LGTM-6191、LGTM-6168) | Vacuum Plate |

| ⑨ Drying Second time | Dryer | TCP Cassette |

| ⑩ Unload Chips | Air Press from Top | Top Press Conversion, Unload Plate |

Single Side Dipping Process from Bottom Inserting

| Dipping Process | Equipment | Consumables |

|---|---|---|

| ① Load Chips | Chip Loading Box, Loading Machine | Load Plate |

| ② Insert Chips (Protrusion) | Air Press from Bottom | Bottom Press Conversion, Top Press Plate (with holes), Thin Carrier Plate, Pins, Spacer for Bottom Insert |

| ③ Level Chips | Air Press for Level | Bottom Level Plate (with flatness), Spacer for Level |

| ④ Dipping First side | TCP Series Dipping Machine (LGTM-6822、LGTM-6191、LGTM-6168) | Vacuum Plate |

| ⑤ Drying First time | Dryer | Cassette |

| ⑥ Transfer Chips (Protrusion) | Air Press from Top | Top Press Conversion, Unload Plate (with holes), Spacer for Transfer |

| ⑦ Level Chips | Air Press for Level | Bottom Level Plate (Flatness), Spacer for Level |

| ⑧Dipping Second side | TCP Series Dipping Machine (LGTM-6822、LGTM-6191、LGTM-6168) | Vacuum Plate |

| ⑨ Drying Second time | Dryer | Cassette |

| ⑩ Unload Chips | Air Press from Top | Top Press Conversion, Unload Plate |