Understand MLCC and Passive Component Automatic Dipping Machines: Principles, Productivity, and Industrial Applications

In modern electronics manufacturing, precision, efficiency, and reliability are critical for success. Among essential processes in MLCC (Multilayer Ceramic Capacitor) and passive component production, automatic dipping machines play a pivotal role in applying conductive paste to chips. Leveraging these machines ensures consistent quality while supporting scalable, high-volume production.

How Automatic Dipping Machines Work in Passive Component Production

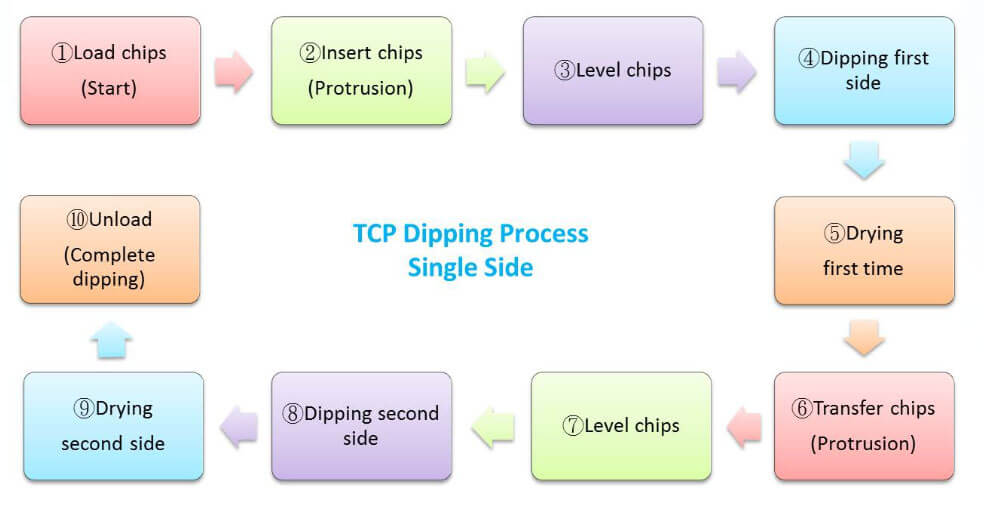

Automatic dipping machines are engineered to deliver uniform and controlled dipping of conductive paste onto passive components such as MLCCs, chip resistors, and inductors. The process begins when components are loaded into Thin Carrier Plates (TCPs) and guided to the dipping station via precise motion control.

Key Steps in Automatic Dipping

- Alignment and Handling

Components are accurately positioned in TCPs, ensuring repeatable and precise dipping. - Dipping and Withdrawal

Controlled height and speed maintain consistent conductive paste thickness, critical for reliability. - Vacuum Debubble Function

Removes trapped air bubbles to prevent defects of the conductive layer. - Drying

Dipped chips are dried before unloading to secure the conductive paste for downstream processes.

This controlled workflow reduces variation, enhances reliability, and improves overall product quality. Compared to manual dipping, automatic dipping machines enable manufacturers to achieve high-volume production with minimal defects.

Process Guide Reference: TCP Dipping Process Single-Side Technology

Measuring Dipping Productivity: Beyond Speed

For production managers, understanding how to calculate productivity is essential in evaluating and comparing dipping systems. In passive component manufacturing, productivity is measured in pieces per hour (pcs/hour), factoring in throughput, yield, and process efficiency.

Productivity Formula for Automatic Dipping Machines

Productivity = (Number of chips per cycle ÷ Cycle time ÷ 2 sides) × Yield rate

- Number of chips per cycle: Determined by chip size and TCP capacity

- Cycle time: Influenced by dipping cycle duration

- Yield rate: Percentage of defect-free outputs

Example:

If one TCP holds 18,128 pieces of 0402 (1005mm) chips, and the dipping cycle time is 40 seconds with a yield rate of 99%:

18128 ÷ (40 × 2) × 60 × 60 × 0.99 = 807,602 chips per hour

This demonstrates that productivity depends on balancing throughput with quality. Optimizing cycle time, dipping uniformity, and yield ensures maximum equipment effectiveness (OEE).

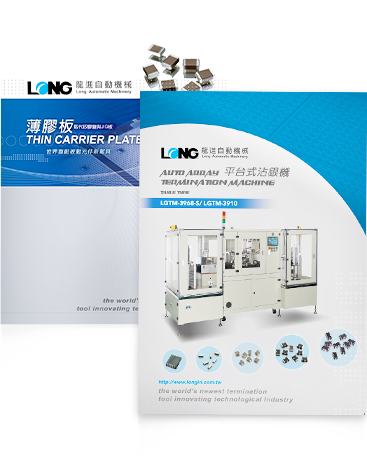

Machine References:

Benefits of Automatic Dipping in Passive Component Manufacturing

Automatic dipping machines provide key advantages for B2B manufacturers:

- Consistent Quality: Uniform termination reduces defects and improves reliability.

- High Throughput: Optimized cycles support large-scale production.

- Operational Efficiency: Automation minimizes labor dependency and human error.

- Scalability: Easily accommodates growing production capacity without compromising quality.

Case Example: LONG Automatic Machinery Co., Ltd.

Manufacturers producing MLCCs, chip resistors, and inductors have leveraged LONG Automatic Machinery Co., Ltd.’s TCP dipping systems to achieve higher throughput and yield. Integrating automatic dipping improves capacity planning, reduces operational costs, and ensures reliable production for global markets.

Conclusion

Automatic dipping machines are the backbone of electrode dipping in passive component production. By combining precise process control with productivity benchmarks, manufacturers can make informed decisions on capacity, cost efficiency, and long-term competitiveness.

Explore LONG Automatic Machinery Solutions or contact us to learn how our automatic dipping systems can enhance production efficiency and reliability in your passive component manufacturing.